My Secure

PVB, EVA & RESIN

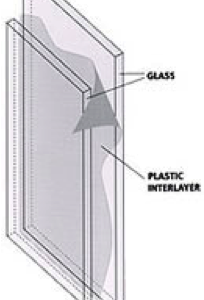

Laminated glass is a combination of two or more glass sheets with one or more inter layers of Poly Vinyl Butyral (PVB),Ethylene and Vinyl Acetate Co-polymer or Resin. In case of breakage, the interlayer holds the fragments together and continues to provide resistance to the passage of persons or objects. This glass is particularly suitable where it is important to ensure the resistance of the whole sheet after breakage such as: shop-fronts, balconies, stair-railings, overhead roof glazing.

The three basic types of laminated glass is PVB, EVA and Resin laminated glass.

PVB & EVA laminated glass is two or more sheets of glass which are bonded together with one or more layers (PVB or EVA) under heat and pressure to form a single piece. Resin laminated glass is manufactured by pouring liquid resin into the cavity between two sheets of glass which are held together until the resin cures.

Multi-ply laminates with three or more glass panes and two or more inter layers are used for use in flooring, fins, beams and other structural applications. Sharda laminate glass is available in traditional float as well as in toughened safety glass.

SENTRY GLASS

SentryGlas interlayers help create lighter, safer, more structurally secure glass that can stand up to greater loads and higher threat levels. Taking advantage of the interlayer’s extra rigidity and toughness, structural glass systems — from floors and stairs to balcony rails and minimally supported glass canopies — can enjoy new design freedom.

Stronger and more rigid than conventional laminating materials, SentryGlas interlayers help create safety glass that protects against bigger storms, larger impacts and more powerful blasts. They become an engineered component within the glass, holding more weight, so the glass can serve as a more active structural element in the building envelope, increasing framing system design freedom.

SentryGlas structural interlayer performance helps architects and glazed building system manufacturers meet society’s need for greater security, energy efficiency, noise reduction, healthful living, safety and maintenance ease. It helps builders do more with less, creating innovative new spaces, while providing greater protection for occupant.

The SentryGlas interlayers are at least, five times stronger and up to 100 times stiffer than conventional laminating materials. With this kind of strength the glass can be a more active structural element in the building envelope, opening up design possibilities that didn’t exist before. Besides its strength, SentryGlas retains its clarity – even after years of service. Unlike other interlayers, SentryGlas is much less vulnerable to moisture exposure or yellowing over time.

BENEFITS

- Strength – equivalent and higher when compared to monolithic glass

- Lighter Weight : up to 40% reduction compared to traditional laminated glass

- Edge Performance

- Enhanced post breakage behaviour : the glass fragments are kept together by the interlayer and the structure will stay in place due to sentry glass intrinsic stiffness.

- Enhanced transparency

- Keeps mechanical properties from low to high temperatures

- Resistant to missile impacts

- Better deflection characteristics

- Used in many bolted glass and minimally supported glass railing applications.

TRANSLUCENT GLASS

If a project requires a frosted look for design or privacy reasons, a translucent colour can be created by adding one of the white interlayers to the colour mix.

Interlayers may be made more translucent in increments. Two of the 13 foundation colours, (colours 9 -Arctic Snow, and A – Cool White) are translucent white interlayers. Cool White (A) is an 80% light transmission product, Arctic Snow (9) is a 65% light transmission product. When these interlayers are used in the Vanceva colour interlayer system, they add opacity to the glazing system. These layers can be used in combination with the other 9 colours or can be laminated alone to produce a frosted glass appearance.

0208 843 1663.

Give us a call today about your glass projects.