My Protect

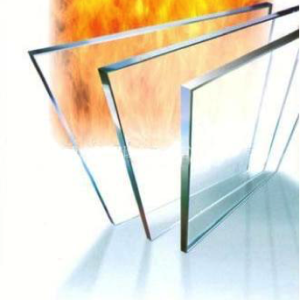

FIRE RESISTANT GLASS

Glass is an increasingly flexible building material and no area better demonstrates this than Fire Resistance. Clear fire resistant glass offers a transparent alternative to a solid brick wall, bringing light and space where previously limited.

There is a clear distinction in the types of protection fire resistant glass offers. Protection is based on either integrity only or integrity with insulation.

- Integrity defines the ability to hold back flames and hot gases. It is essentially a barrier to the spread of flames but does not stop heat.

- Insulation is a much higher level of performance which limits heat transfer from the fire, both providing a barrier to the spread of flame and stopping heat by all heat transfer mechanisms through the glass

The distinction between these two performance classes must not be blurred, as the differences in performance – and consequences in a fire – can be huge. Integrity only may lead to high temperature conditions on the fired side and levels of radiant heat that cause both serious life-threatening burns to people and secondary ignition of objects on the non fire side of the glazing. Integrity and insulation provides the barrier to fire and excellent protection against heat giving crucial advantages for enhanced life safety, as well as benefits in limiting fire spread in condition of exposure which may be hours not minutes.

Readily available is monolithic wired fire glass. It offers reliable, integrity only, fire-resistant glazing in a range of applications, including doors, screens and overhead glazing. It can also be used in a variety of internal and external applications for vision or privacy purposes.

BULLET RESISTANT GLASS

Bullet Resistant glass also known as ballistic glass, transparent armour or bullet proof glass is a type of strong but optically transparent material that is particularly resistant to being penetrated when struck by bullets, but like all known materials, is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so it can flex instead of shatter. The index of refraction for both of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear view (not distorted) through the glass.

Bullet-resistant glass is usually constructed using polycarbonate, thermoplastic, and layers of laminated glass. The aim is to make a material with the appearance and clarity of standard glass but with effective protection from small arms. Polycarbonate designs usually consist of products such as Armormax, Makroclear, Cyrolon, Lexan or Tuffak, which are often sandwiched between layers of regular glass. The ability of a glass itself to withstand shock is improved by the process of tempering. When treated with heating and cooling or with chemical processes, the glass becomes much stronger. The polycarbonate usually has one of two types of coating to resist abrasion: a soft coating that heals after being scratched (such as elastomeric carbon-based polymers) or a hard coating that prevents scratching (such as silicon-based polymers)

The plastic in laminate designs also provides resistance to impact from physical assault from hammers, axes, clubs, and so forth. The plastic provides little in the way of bullet-resistance. The glass, which is much harder than plastic, flattens the bullet, and the plastic deforms, absorbing the rest of the energy and preventing penetration. The ability of the polycarbonate layer to stop projectiles with varying energy is directly proportional to its thickness, and bulletproof glass of this design may be up to three inches thick. Laminated glass layers are built from glass sheets bonded together with polyvinyl butyral, polyurethane or ethylene-vinyl acetate. This design has been in regular use on combat vehicles since World War II; it is typically 100-120 millimetres (3.9-4.7 inches) thick and is usually extremely heavy.

ACOUSTIC GLASS

Acoustic glass can be functional to both commercial and domestic buildings when applied to products such as windows, patio doors, skylights, conservatories and internal screens and partitions. It can also be incorporated within double glazed units ranging in thickness from 26mm – 40mm, as well as single glazed applications from 6.8mm to 16.8 mm in thickness. Acoustic glass is made with assembly with two or more panes of glass with one or more PVB. At least one of the interlayers must be acoustic interlayer.Acoustic glass is a perfect solution for insuring exceptional levels of sound insulation. It not only provides insulation for impact and airborne noise but also maintains the safety and security properties of laminated glass.

BENEFITS

- High level acoustic performance

- Mechanical performance equivalent to normal PVB in terms of safety

- Can be combined with other glasses to offer other functions: solar control, decoration, enchanced thermal insulation.

- Used for exterior and interior applications in monolithic or double glazing.

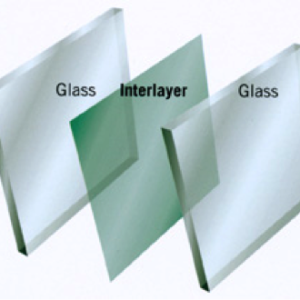

LAMINATE GLASS

Laminated glass is a type of safety glass that holds together when shattered. In the event of breaking, it is held in place by an interlayer, typically of polyvinyl butyral (PVB), between its two or more layers of glass. The interlayer keeps the layers of glass bonded even when broken, and its high strength prevents the glass from breaking up into large sharp pieces. This produces a characteristic “spider web” cracking pattern when the impact is not enough to completely pierce the glass. Laminated glass is normally used when there is a possibility of human impact or where the glass could fall if shattered.

The PVB interlayer also gives the glass a much higher sound insulation rating, due to the damping effect, and also blocks 99% of transmitted UV light.

Laminated Glass is a multifunctional glazing material that can be used in a variety of applications:

- Sloped/Overhead Glazing

- Museums, Prisons, Government Buildings

- Jewellery Stores, Banks, Airports

- Safety Glazing Applications

- Schools, Hospitals, Hotels

- Interior Partitions, Office Buildings.

TOUGHENED GLASS

Toughened glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. The high compressive surface stresses give the glass its increased resistance to mechanical and thermal stresses. It can, however, break under extreme loads or by severe impact. When broken, toughened glass shatters into small, blunt-edged fragments, reducing the risk of personal injury. Toughened glass is five times stronger than ordinary glass of the same thickness. Available in thickness from 4mm – 19mm.

Toughened glass is intended for glass facades, sliding doors, building entrances, bath and shower enclosures and other uses requiring superior strength and safety properties.

There are two different methods used to produce tempered glass:

Heat Strengthened: The Heat strengthening process changes the surface compression of the glass usually to a level greater than 4000psi and less than 7000 psi. In turn the glass becomes 2 – 3 times stronger than normal annealed glass (it is not classed as a safety glass). Heat strengthened glass has three main criteria, Thermal Safety, Reduced Surface Distortion and when broken the glass cracks into large particles, whilst maintaining rigidity giving improved retention in the glazing system thus reducing the chances of falling glass.

Toughened : Toughened glass is produced from float glass via a thermal tempering process. The glass is cut to the required size and required processing (such as polishing the edges or drilling holes in the glass) is carried out before the toughening process starts.The toughening process must be the final stage of glass production because any attempt to cut toughened glass will cause it to shatter.

The treatment involves heating the glass to 700 degrees celsius so that it begins to soften. The glass is then rapidly cooled with forced draughts of air. This rapidly cools the glass surface below its annealing point, causing it to harden and contract, while the inner portion of the glass remains free to flow for a short time.The final contraction of the inner layer induces compressive stresses in the surface of the glass. It is this compressive stress that gives the toughened glass an increased strength.

NON-REFLECTIVE GLASS

Non reflective glass is float glass with a specially-designed coating which reflects a very low percentage. It offers maximum transparency and optical clarity, allowing optimum viewing through the glass at all times. The clarity of vision makes anti-reflective glass suitable for all applications where glass should be transparent.

Applications:

Shop fronts and commercial frontages, glazing where vision is important, particularly at night time such as panoramic restaurants, air traffic control towers, petrol station windows. High quality picture framing, display cabinets and interior display windows, dividing screens in cinema projection rooms, television studios, machine control rooms etc.

Advantages :

- High light transmission; 98% vs 91% for ordinary float glass

- Can be installed in any frame or glazing system suitable for regular window glass

- Can be tempered or laminated for safety glazing

- Cuts cooling costs because less lighting is required to overcome glare

- Cuts construction costs; there’s no need to provide awnings or tilted glazing to control glare

- Less fading of displayed items, thanks to reduced UV transmission

- Increases sales appeal of displayed products; also allows entire store interior to become part of general window display

Greater visibility in monitoring applications, resulting in greater accuracy and safety - Enhances the view in places like restaurants throughout the day; eliminates the glare which often occurs at certain morning, afternoon, and evening hours

- Displayed colours appear truer

STRUCTURAL BONDING

Structural Bonding is a method of bonding glass to a metal frame, stainless steel, aluminium, galvanised steel and steel this gives the advantage that the glazing from the outside appears to be frameless. Generally the glazed units are bonded to a carrier frame which is in turn bolted to a framed cladding structure.

Structural Bonding is a brilliant, cost effective solution for contemporary glass design. Structural Glazing systems consist of a fully or partially framed internal finish, with the glass structurally glazed/adhered to the outside face. All to produce a complete flush silicone jointed external finish. Whilst the framed internal appearance is more traditional, structural bonding provides a high flexibility in regards to the sections utilised and framework finish.

SANDBLASTED GLASS

Sandblasted glass is a very versatile form of decorative glass and is an ideal application for traditional door designs and contemporary commercial projects. Sandblasted glass gives an amazing decorative effect without taking away much of the natural daylight.

Sandblasted panels are produced by spraying sand at high velocities over the surface of the glass. This gives the glass a translucent surface, which is usually rougher than that obtained by etching. During sandblasting, only the areas that are to remain transparent are masked for protection. The depth and degree of the translucency of the sand-blasted finishing vary with the force and type of sand used. Sand-blasted glass can be used in numerous interior design applications in both residential and commercial settings: doors, shower screens, partitions and interior screens, furniture, etc.

BACK PAINTED GLASS

In addition to coloured glass from our range we can offer you back painted glass, this enables you to choose the colour you require to accompany your own decor. Give us the colour code and we’ll do the rest. Colour backed glass is also available in annealed and laminated forms. This is becoming more popular in domestic applications such as glass splash backs in kitchens and cladding on bathroom walls.

We can match from RAL and BS colour references and also from the Dulux Trade Palette When choosing colours please also be aware that normal float glass has a green tint to it. If a perfect colour match is required we would recommend that ‘low iron’ extra white glass be used in 6mm for splash backs and 19mm for worktops. Low iron glass can be toughened and processed in the same way as float glass.

0208 843 1663.

Give us a call today about your glass projects.